Short Lead Time for Foundry Mould - Cast Steel nozzle – Yungong

Short Lead Time for Foundry Mould - Cast Steel nozzle – Yungong Detail:

Metal diversion tube decompose gas and improve the efficiency of heat exchange.

Applicable to all fields

Stainless Steel:

The main alloys of stainless steel are chromium, nickel, and molybdenum, which determine the grain and mechanical properties of the casting.

How the alloys are combined decides how the casting will be able to endure heat and resist corrosion.

Since stainless steel is 10% chromium, it is resistant to liquid corrosive conditions and oxidation.

Steel:

Carbon, low alloy, and tool steels are used in the aerospace, agricultural, medical, and firearm industries, to name a few.

Steel is chosen for lost wax casting because it is economical, available in several grades, and can be heat treated to adjust its ductility.

Lost wax casting, or investment casting is used to produce parts that require tight tolerances that can have thinner walls with surface finishes that require little after process finishing.

A unique feature of lost wax casting is how it recreates a CAD design using wax to create the pattern of the piece to be manufactured.

The casting process for lost wax casting involves multiple steps that begin with the creation of the pattern, or master, from aluminum.

The method for creating the pattern determines its replicability.

Benefits of investment casting over sand casting

All casting methods offer many design benefits: the ability to minimize material inputs, and to form structures that would be otherwise difficult to achieve without significant machining or assembly.

A key benefit of investment casting, however, is the versatility of its mold.

Because the mold is expendable, and because wax patterns can be removed unobtrusively in liquid form, manufacturers have an exceptional amount of freedom when designing investment cast products.

Investment casting provides much for much more complex design capabilities than most other molding and casting methods.

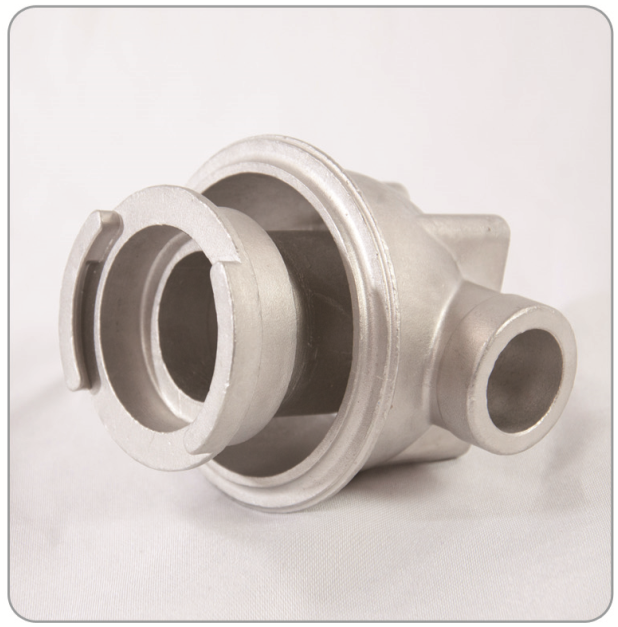

Product detail pictures:

Related Product Guide:

How is the strength of the silica sol shell made?

We take pleasure in an extremely fantastic standing among the our prospects for our great product high quality, competitive cost and the support for Short Lead Time for Foundry Mould - Cast Steel nozzle – Yungong , The product will supply to all over the world, such as: Panama, Nigeria, America, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we've got better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We have been always here working for your demands whenever you require.

Products description

precision casting stainless steel parts have a wide range of applications. The precision casting are widely used in aviation, navigation, medical, mining, automotive, decoration, food machinery and other industries .

our casting including pump valve , Pipe fittings, impeller, nozzle, Marine accessories, energy and mineral accessories. Auto parts, Food machinery accessories, Fire escape fittings, medical device accessories, decoration parts

our factory

Shijiazhuang Yungong technology company Located in Xing tang County Economic and Technological Development Zone, Shijiazhuang City, He bei Province,The company covers an area of twenty thousand square meters .It is a large investment casting production base with more than 300 employees,

we have research and development, design. Manufacture. Sale and after service departments.

The company is mainly engaged in precision casting .Our precision casting uses medium temperature wax. Silica sol shell making process

Products picture

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.